TB vs Plenum Size

TB vs Plenum Size

Hey there everyone.

I have been reading up a little on what makes the ideal setup in terms of plenum size vs throttle body size for engines.

I have sent off a TS magna manifold to Stealth for him to modify it to fit into my LA lancer, but I am unsure of what size TB to go for...

From what I have read, a small TB works well with a large plenum, and a large TB works well with a small plenum. However I have no real idea as to what BIG and SMALL are.

So what is everybody running? 60mm TB 70mm TB on and what size plenums?

This would be for an NA 2.6 build (with extractors, if that makes a difference).

Cheers

Rob

I have been reading up a little on what makes the ideal setup in terms of plenum size vs throttle body size for engines.

I have sent off a TS magna manifold to Stealth for him to modify it to fit into my LA lancer, but I am unsure of what size TB to go for...

From what I have read, a small TB works well with a large plenum, and a large TB works well with a small plenum. However I have no real idea as to what BIG and SMALL are.

So what is everybody running? 60mm TB 70mm TB on and what size plenums?

This would be for an NA 2.6 build (with extractors, if that makes a difference).

Cheers

Rob

4dr LA Lancer

CBR600rr 07

CBR600rr 07

- EVL076

- S-G Veteran

- Posts: 480

- Joined: Mon Mar 16, 2009 10:08 pm

- Location: Baggin' 4th and chirpin' 5th

Re: TB vs Plenum Size

i am running an 80mm TB on an 8 litre Plenum

everything i have on/for my motor is BIG

big turbo, big injectors, big plenum, big throttle body, big exhaust, big shot of nitrous, big spring in the wastegate, big fuel system....

WHY??

cos i want big power

everything i have on/for my motor is BIG

big turbo, big injectors, big plenum, big throttle body, big exhaust, big shot of nitrous, big spring in the wastegate, big fuel system....

WHY??

cos i want big power

Re: TB vs Plenum Size

I kind of figured it would be a less delicate balance if the system has a turbo, because the positive pressure would cancel a lot of the flow/pressure issues.

Good to know though.

BTW is Stealth on holidays?

Cheers

Rob

Good to know though.

BTW is Stealth on holidays?

Cheers

Rob

4dr LA Lancer

CBR600rr 07

CBR600rr 07

Re: TB vs Plenum Size

i've got a TR Magna throttle body on a TP injection manifold in my LC .No height modification was necessary...I just chopped the 2 inches of the TR inlet that the throttle body of the TR bolts to ,and welded that onto the front of the TP inlet.

TR Tb is bigger than TP but I don't know how much by.

Runs great

TR Tb is bigger than TP but I don't know how much by.

Runs great

Re: TB vs Plenum Size

I used a xf throttle body which i think is like 75mm on my starion 2L 4g63 sohc engine and i have found it to be very very touchy on the accelerator. I found i would also have to ride the clutch when in first gear due to the relatively large amount of air flow at small openings. I think i would prefer a smaller throttle body on an engine of that size but i already had it tuned for that set up and couldn't be bothered changing anything.

Instead i will change the opening characteristics of the throttle so that pressing the accelerator just a little makes a smaller difference opening of the throttle and making when you put your foot down the throttle open much faster. This would provide a much better control at the low rev's and still allow for full throttle when you press on the accelerator pedal. I can explain in more detail how i plan to do that if anyone is actually interested.

Instead i will change the opening characteristics of the throttle so that pressing the accelerator just a little makes a smaller difference opening of the throttle and making when you put your foot down the throttle open much faster. This would provide a much better control at the low rev's and still allow for full throttle when you press on the accelerator pedal. I can explain in more detail how i plan to do that if anyone is actually interested.

'72 GB Galant Sedan nanna spec daily

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

- DanTurboLancer

- Posts: 1382

- Joined: Wed Mar 25, 2009 1:19 pm

- Location: Newcastle N.S.W Australia

Re: TB vs Plenum Size

Yes i am interested in what you have planned WOOPS.

But also i would ask have you driven a car with the same set up, but smaller Throttle body, or indeed Larger Plenum, to compaire its driveabilty to your current set up?

I guess Robs actuall question is more for anyone that has done a direct comparison, or have any info about the actual benefits of using what sizes etc??

But also i would ask have you driven a car with the same set up, but smaller Throttle body, or indeed Larger Plenum, to compaire its driveabilty to your current set up?

I guess Robs actuall question is more for anyone that has done a direct comparison, or have any info about the actual benefits of using what sizes etc??

Re: TB vs Plenum Size

OK i haven't driven a vehicle with a similar setup to mine but with a different throttle body or plenum.

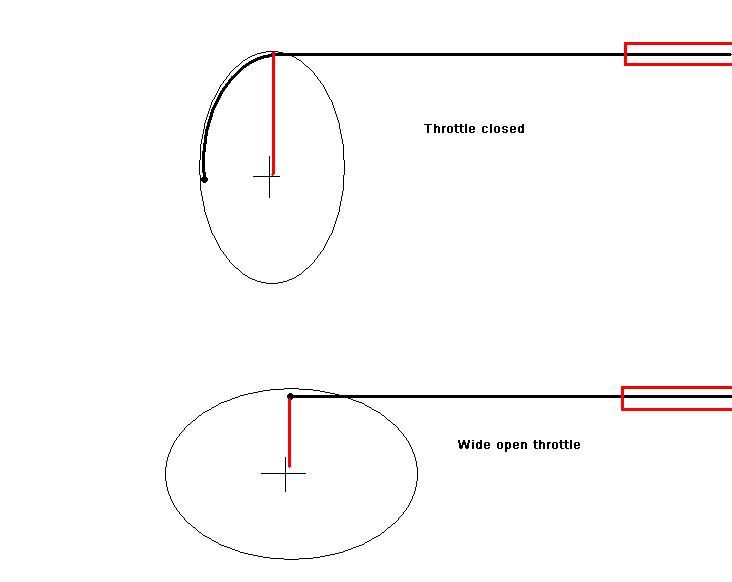

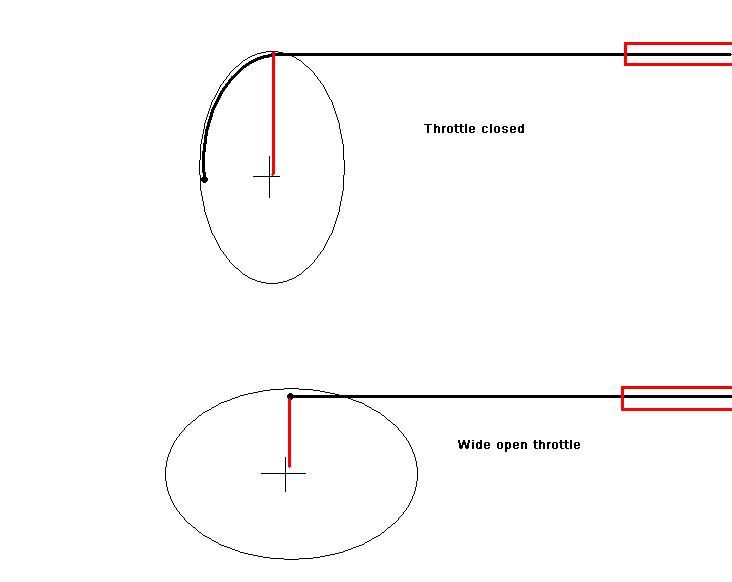

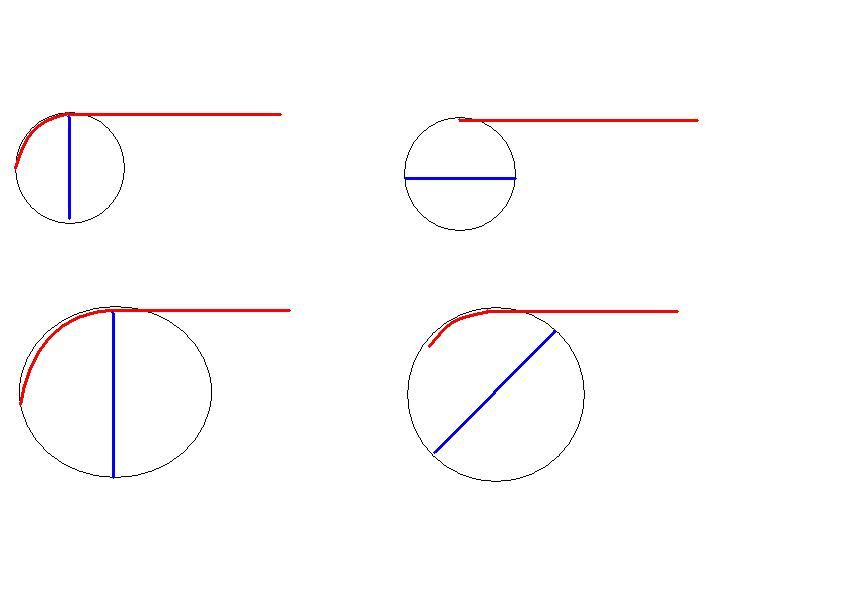

The only reason why i am actually sticking with the xf throttle body is that i don't want to have retune the engine just for the sake of a throttle body change. The plan to be able to make the car more drivable to to fabricate a different cam where the cable goes to suit the different application. When i mean cam i actually mean the shape of the throttle cable guide on the side of the throttle body. You may have noticed how on the ebay custom style throttle bodys they have just a circular disc where the cable mounts like this

but on standard factory throttle body you see the shape is somewhat like a cam shape. They typically have the diameter of the throttle cable guide larger when you just start to open the throttle and smaller diameter when the throttle is fully open. They do this so that when the accelerator pedal is pressed for say the first 20% the throttle only opens 10 degrees and at full throttle when the a accelerator pedal is pressed say the last 20% the throttle opens the final 20 degrees. keep note that the throttle only travels 90 degrees. These figures are only theoretical values to give you the idea of what happens.

Basically the problem i have is that putting a XF throttle body designed for a 4.1L engine onto my a 2L engine is that when i press the throttle by 20% i actually get about double the airflow required when compared to the falcon engine. This means that instead of pressing the throttle by 20% and getting enough airflow for 2000rpm i actually get enough airflow for 4000rpm. There won't be as big an effect for the 2.6L engine but for the same scenario of pressing the accelerator pedal by 20% you would get enough airflow for about 3150rpm or in other words about 60% extra flow.

Basically what i am planning on doing is changing the cam profile to have say the first 20% of accelerator pedal move the throttle by only 5 degrees (this is instead of the 10 degrees from the falcon actuator) to decrease the low accelerator pedal sensitivity and have the throttle open by say 40 degrees for the final 20% of accelerator pedal movement. These figures won't actually be the same as the real figures but i will be still having the same multiplying factor applied. This would mean the first 50% of accelerator pedal movement would be half the throttle opening and the top 50% would have double the original falcon degree of throttle opening.

I will probably have to do a sketch to show what i mean but essentially all this will allow for the low rpm control required and the large top end airflow as desired.

The only reason why i am actually sticking with the xf throttle body is that i don't want to have retune the engine just for the sake of a throttle body change. The plan to be able to make the car more drivable to to fabricate a different cam where the cable goes to suit the different application. When i mean cam i actually mean the shape of the throttle cable guide on the side of the throttle body. You may have noticed how on the ebay custom style throttle bodys they have just a circular disc where the cable mounts like this

but on standard factory throttle body you see the shape is somewhat like a cam shape. They typically have the diameter of the throttle cable guide larger when you just start to open the throttle and smaller diameter when the throttle is fully open. They do this so that when the accelerator pedal is pressed for say the first 20% the throttle only opens 10 degrees and at full throttle when the a accelerator pedal is pressed say the last 20% the throttle opens the final 20 degrees. keep note that the throttle only travels 90 degrees. These figures are only theoretical values to give you the idea of what happens.

Basically the problem i have is that putting a XF throttle body designed for a 4.1L engine onto my a 2L engine is that when i press the throttle by 20% i actually get about double the airflow required when compared to the falcon engine. This means that instead of pressing the throttle by 20% and getting enough airflow for 2000rpm i actually get enough airflow for 4000rpm. There won't be as big an effect for the 2.6L engine but for the same scenario of pressing the accelerator pedal by 20% you would get enough airflow for about 3150rpm or in other words about 60% extra flow.

Basically what i am planning on doing is changing the cam profile to have say the first 20% of accelerator pedal move the throttle by only 5 degrees (this is instead of the 10 degrees from the falcon actuator) to decrease the low accelerator pedal sensitivity and have the throttle open by say 40 degrees for the final 20% of accelerator pedal movement. These figures won't actually be the same as the real figures but i will be still having the same multiplying factor applied. This would mean the first 50% of accelerator pedal movement would be half the throttle opening and the top 50% would have double the original falcon degree of throttle opening.

I will probably have to do a sketch to show what i mean but essentially all this will allow for the low rpm control required and the large top end airflow as desired.

'72 GB Galant Sedan nanna spec daily

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

Re: TB vs Plenum Size

Ah I get you, I had wondered why the shape on the VN TB I have wasn't circular like the after-market jobs I have seen.

A few questions then, would a circular profile (like after-market) be better than the lobed factory ones or worse, in your case?

When you were describing the opening characteristics of the TB is the pedal more sensitive (moves the TB more degrees) at the start of opening or at wide open?

Just for the update, I am considering the 70mm after-market TB for the 2.6 at this stage with a circular throttle wheel

Regards

Rob

A few questions then, would a circular profile (like after-market) be better than the lobed factory ones or worse, in your case?

When you were describing the opening characteristics of the TB is the pedal more sensitive (moves the TB more degrees) at the start of opening or at wide open?

Just for the update, I am considering the 70mm after-market TB for the 2.6 at this stage with a circular throttle wheel

Regards

Rob

4dr LA Lancer

CBR600rr 07

CBR600rr 07

Re: TB vs Plenum Size

You want the throttle to be less sensitive when you are just opening the throttle.

And in my case the aftermarket circular actuator would be much much worse. The lobed ones make much less sensitivity when the throttle just starts to open. This is due to the larger radius at closed throttle compared to the radius at wide open throttle. You want the least change in angle of the throttle plate near the closed throttle as that is where the largest change in airflow occurs with the change in the angle of opening. When the throttle opens by say 5% then the airflow actually coming though would be something like 15% of the total maximum airflow. You would also probably find that the difference between the throttle open say 60% and 100% would only be a small change in air flow. The cam lobe reduces the amount of which the throttle opens when the accelerator is initially pressed and makes the change in rpm much more predictable and controllable.

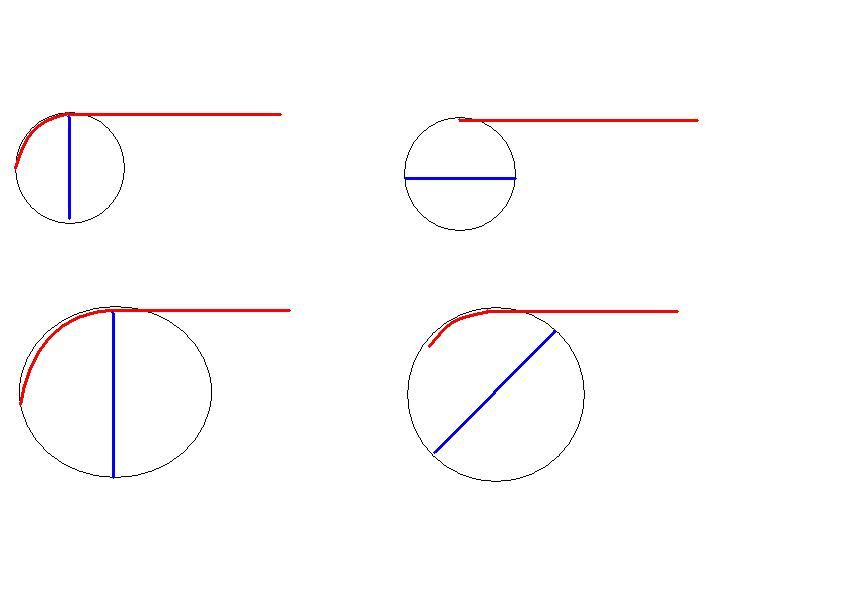

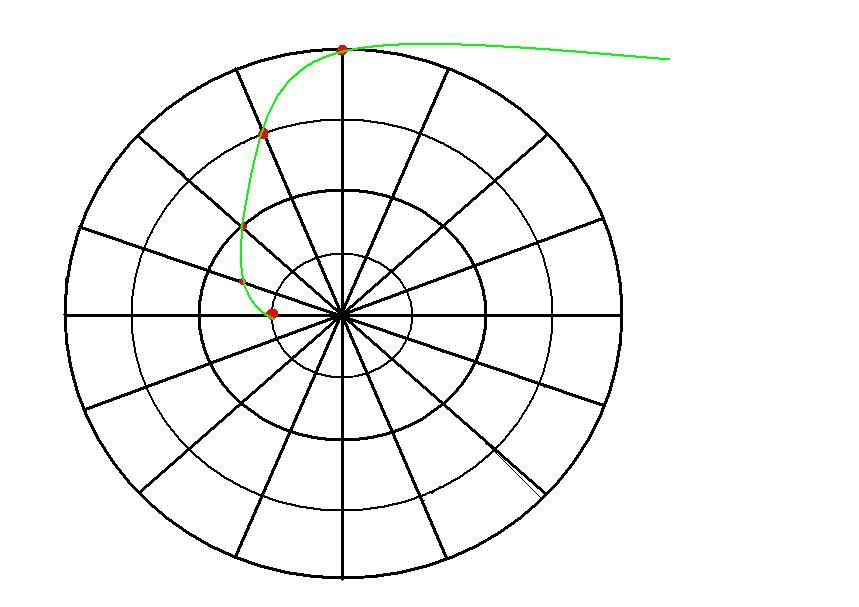

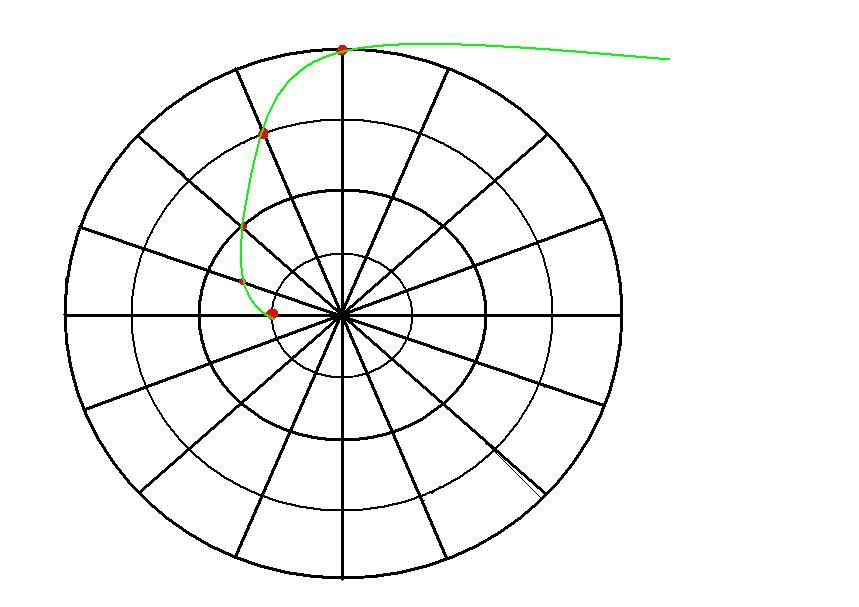

Think about it this way. Compare two different actuators with one that has a radius of 25mm and the other of 50mm. Using basic trigonometry you can find how much accelerator cable is needed to rotate the throttle plate by 90 degrees. As the throttle cable sits on the outside circumference the simple formula (2 x Pi x Radius) x (90 degrees / 360 degrees) can be used to find the throttle cable length needed to move the throttle from fully closed to fully open. The 25mm actuator needs 40mm of accelerator length movement to rotate 90 degrees. If that same amount of cable movement is used on the larger throttle actuator you would only get 45 degrees of movement. I've shown it graphically below.

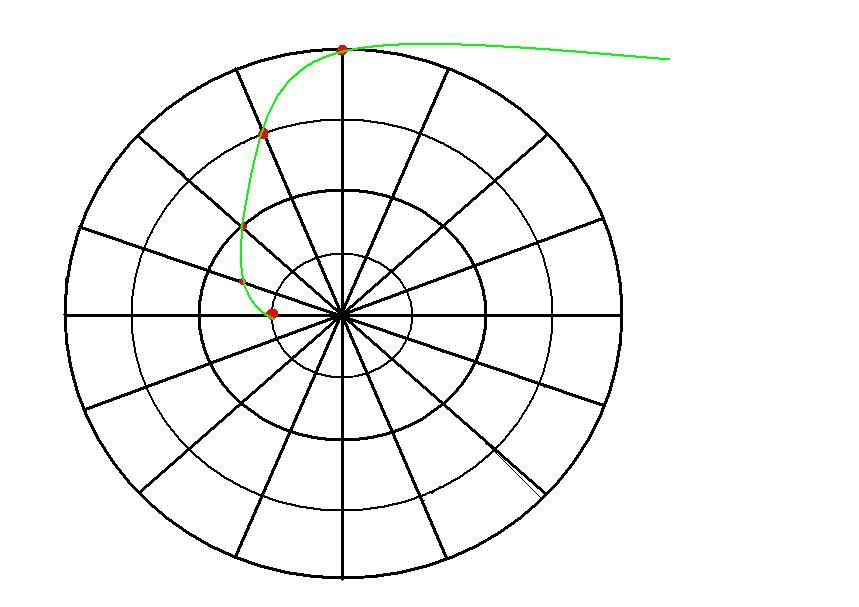

It's actually really easy to design the cam lobe needed for the accelerator actuator. I've done a little sketch to give you an idea of how to do it. The sketch shows the throttle movement would be 4 times less sensitive when you just start to press the accelerator pedal than at full throttle. This is due to the radius being 4 times larger at the closed throttle position than the open throttle position. To design it all you need to do is ensure that you have enough change in accelerator length to go from closed to fully open throttle.

I don't know if i have explained everything that clearly so let me know if there is anything else. I'm actually surprised i've never seen this done at all in the automotive modification sector as i'm sure i'm not the first to have this problem. Maybe others like to have a accelerator pedal which is more like a on and off switch.

And in my case the aftermarket circular actuator would be much much worse. The lobed ones make much less sensitivity when the throttle just starts to open. This is due to the larger radius at closed throttle compared to the radius at wide open throttle. You want the least change in angle of the throttle plate near the closed throttle as that is where the largest change in airflow occurs with the change in the angle of opening. When the throttle opens by say 5% then the airflow actually coming though would be something like 15% of the total maximum airflow. You would also probably find that the difference between the throttle open say 60% and 100% would only be a small change in air flow. The cam lobe reduces the amount of which the throttle opens when the accelerator is initially pressed and makes the change in rpm much more predictable and controllable.

Think about it this way. Compare two different actuators with one that has a radius of 25mm and the other of 50mm. Using basic trigonometry you can find how much accelerator cable is needed to rotate the throttle plate by 90 degrees. As the throttle cable sits on the outside circumference the simple formula (2 x Pi x Radius) x (90 degrees / 360 degrees) can be used to find the throttle cable length needed to move the throttle from fully closed to fully open. The 25mm actuator needs 40mm of accelerator length movement to rotate 90 degrees. If that same amount of cable movement is used on the larger throttle actuator you would only get 45 degrees of movement. I've shown it graphically below.

It's actually really easy to design the cam lobe needed for the accelerator actuator. I've done a little sketch to give you an idea of how to do it. The sketch shows the throttle movement would be 4 times less sensitive when you just start to press the accelerator pedal than at full throttle. This is due to the radius being 4 times larger at the closed throttle position than the open throttle position. To design it all you need to do is ensure that you have enough change in accelerator length to go from closed to fully open throttle.

I don't know if i have explained everything that clearly so let me know if there is anything else. I'm actually surprised i've never seen this done at all in the automotive modification sector as i'm sure i'm not the first to have this problem. Maybe others like to have a accelerator pedal which is more like a on and off switch.

'72 GB Galant Sedan nanna spec daily

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

Re: TB vs Plenum Size

woops, i know exactly what your on about

ive got the same happening on mine with a falcoon throttle, its difficult to take off slowly as the slightest touch of the throttle and its revving to 3k

add a 2400lb clutch and its heaps of fun to drive in peak hour.... NOT!

People think im full of shit when i tell them its difficult to drive in the wet without spinning the wheels on take off a little.

i was planning on changing the lobe on the TB aswell to try and make it more streetable

ive got the same happening on mine with a falcoon throttle, its difficult to take off slowly as the slightest touch of the throttle and its revving to 3k

add a 2400lb clutch and its heaps of fun to drive in peak hour.... NOT!

People think im full of shit when i tell them its difficult to drive in the wet without spinning the wheels on take off a little.

i was planning on changing the lobe on the TB aswell to try and make it more streetable

Insert witty one liner here -->

- DanTurboLancer

- Posts: 1382

- Joined: Wed Mar 25, 2009 1:19 pm

- Location: Newcastle N.S.W Australia

Re: TB vs Plenum Size

Very good WOOPS!

I see that working well for your problem!!

(I realise that is Capatain Obvious for most)

But i would say the main reason Aftermarket Throttle body "Actuators" are round,

is because its just easy and cheap to machine.

I am not much of a machinist at all, others may be able to give you a better idea here.

But i am thinking machining an arc like that may be abit of skill??

Perhaps Offsetting the Hole that is mounted onto a round throttle body butterfly shaft might have the same effect?

I see that working well for your problem!!

Obviously you would have to make that a smooth arch, so you dont have a notchy throttle response.woops wrote:

(I realise that is Capatain Obvious for most)

But i would say the main reason Aftermarket Throttle body "Actuators" are round,

is because its just easy and cheap to machine.

I am not much of a machinist at all, others may be able to give you a better idea here.

But i am thinking machining an arc like that may be abit of skill??

Perhaps Offsetting the Hole that is mounted onto a round throttle body butterfly shaft might have the same effect?

Re: TB vs Plenum Size

Yeah i just did that sketch with paint so it's a bit rough. It's much easier to draw the right shape on paper as you can always put in more lines radiating from the centre and easier to smooth out the curve too.

Also they would have the round actuator as it looks much cleaner and simpler. Also the other thing is that the shape of the actuator would be slightly different for each engine. The larger engines wouldn't need so much of a lobe as the smaller engines.

I have absolutely no machining ability but i've already planned how i'm gonna make this. I picked up some 5mm alloy from the scrap metal yard and i was just gonna cut and file it to the required shape. I was then going to sandwich this between two thin plates to cut the holes needed to insert the end of the cable and to retain the cable. I was then just going to bolt this to the original cable mounting plate. It's a bit hard to fabricate something from scratch to suit the falcon throttle shaft. Easy enough to do all this with just a drill, files and angle grinder.

Also they would have the round actuator as it looks much cleaner and simpler. Also the other thing is that the shape of the actuator would be slightly different for each engine. The larger engines wouldn't need so much of a lobe as the smaller engines.

I have absolutely no machining ability but i've already planned how i'm gonna make this. I picked up some 5mm alloy from the scrap metal yard and i was just gonna cut and file it to the required shape. I was then going to sandwich this between two thin plates to cut the holes needed to insert the end of the cable and to retain the cable. I was then just going to bolt this to the original cable mounting plate. It's a bit hard to fabricate something from scratch to suit the falcon throttle shaft. Easy enough to do all this with just a drill, files and angle grinder.

'72 GB Galant Sedan nanna spec daily

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

-

Superscan811

- Posts: 1689

- Joined: Sun Mar 22, 2009 4:12 pm

- Location: Sydney

Re: TB vs Plenum Size

Before you get too excited, have a look at the TP throttle actuator.

This may well be enough.

Cheers.

This may well be enough.

Cheers.

Re: TB vs Plenum Size

ive got the tp arm on the ford TB its still too touchy for daily use.

although ive got counter shafts deleted and a 2L flywheel which makes it a MUCH revvier engine than the std 2.6

although ive got counter shafts deleted and a 2L flywheel which makes it a MUCH revvier engine than the std 2.6

Insert witty one liner here -->

Re: TB vs Plenum Size

Yeah that's similar to what the xf throttle body has too. That looks as though it has the large radius about 2 times the smaller one. I plan to have pretty much 4 times the difference between the large and small radius. That should hopefully make it a little easier to drive then.

'72 GB Galant Sedan nanna spec daily

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project

'85 GN Sigma Wagon 4g63 SOHC Turbo almost ready for the road

'74 GC Galant Coupe long term project